What Is Alucobond: A Versatile Building Material

Alucobond, a brand of aluminum composite material (ACM), has become a popular choice in the construction industry due to its versatility, durability, and aesthetic appeal. This lightweight cladding material consists of two aluminum cover sheets bonded to a non-aluminum core, resulting in a strong and rigid panel. In this article, we will explore the various characteristics and applications of Alucobond, highlighting its benefits and considerations for architects, builders, and designers.

Section 1: Composition and Structure

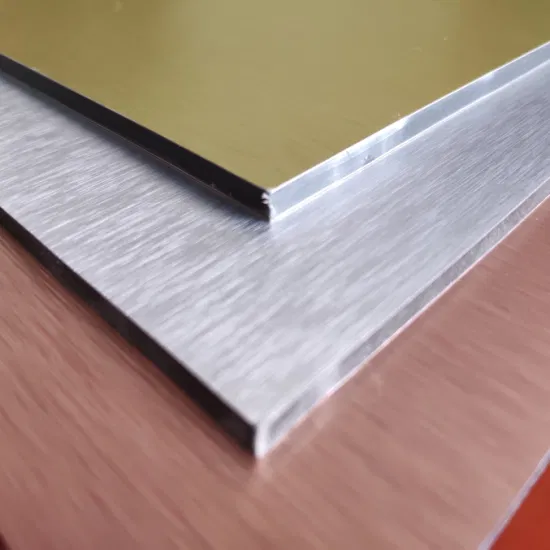

Alucobond panels are composed of two thin aluminum sheets that are coil-coated with a high-quality paint finish. These sheets are then bonded to a non-aluminum core, typically made of polyethylene (PE) or fire-retardant (FR) mineral-filled material. The core acts as an insulator, providing thermal and sound insulation properties to the panel. The combination of the aluminum cover sheets and the core results in a lightweight yet sturdy material that is easy to handle and install.

The aluminum cover sheets used in Alucobond panels are typically made from alloy 3003 or 5005. These alloys offer excellent corrosion resistance, ensuring the longevity of the panels even in harsh weather conditions. The surface of the aluminum sheets can be coated with a wide range of finishes, including solid colors, metallics, and natural metal appearances like zinc or copper. This allows architects and designers to achieve their desired aesthetic while maintaining the durability and performance of the material.

Section 2: Advantages of Alucobond

Alucobond offers several advantages that make it a preferred choice for architectural cladding. Firstly, its lightweight nature reduces the load on the building structure, making it easier and more cost-effective to transport and install. The panels can be easily cut, bent, and shaped to meet the specific design requirements, allowing for creative freedom and flexibility.

Secondly, Alucobond panels are highly durable and require minimal maintenance. The aluminum cover sheets provide excellent resistance to UV radiation, fading, and weathering, ensuring that the panels retain their appearance over time. Additionally, the panels are resistant to fire, moisture, and chemicals, making them suitable for a wide range of applications.

Another significant advantage of Alucobond is its thermal and sound insulation properties. The non-aluminum core acts as an effective insulator, reducing heat transfer and improving energy efficiency. This can contribute to lower heating and cooling costs for buildings, making Alucobond a sustainable choice.

Section 3: Applications of Alucobond

Alucobond panels find extensive use in both commercial and residential buildings. Their versatility allows them to be used for exterior cladding, interior wall panels, signage, and even furniture design. In exterior applications, Alucobond panels can be used to create striking facades, adding a modern and sleek appearance to the building. The wide range of finishes available allows architects to achieve various design styles, from contemporary to traditional.

In interior applications, Alucobond panels can be utilized for wall cladding, partitions, and ceilings. The panels provide a clean and seamless look, enhancing the overall aesthetics of the space. Additionally, Alucobond’s acoustic properties make it suitable for areas where sound insulation is crucial, such as auditoriums or conference rooms.

Section 4: Considerations and Maintenance

While Alucobond offers numerous benefits, there are some considerations to keep in mind when using this material. Firstly, proper installation is crucial to ensure the longevity and performance of the panels. It is essential to follow the manufacturer’s guidelines and use experienced installers who are familiar with Alucobond’s installation requirements.

Regular maintenance is also necessary to preserve the appearance of Alucobond panels. Cleaning the panels periodically with mild detergent and water can help remove dirt and debris. Harsh chemicals or abrasive cleaners should be avoided to prevent damage to the paint finish. Additionally, any scratches or dents should be repaired promptly to prevent moisture ingress and maintain the integrity of the panels.

Conclusion:

Alucobond has emerged as a versatile and durable building material that offers architects, builders, and designers a wide range of design possibilities. Its lightweight nature, durability, and aesthetic appeal make it an ideal choice for exterior and interior applications. With proper installation and maintenance, Alucobond panels can provide long-lasting performance while enhancing the visual appeal of buildings.